Dry Aseptic Filling Decontamination System

for CSD & Still

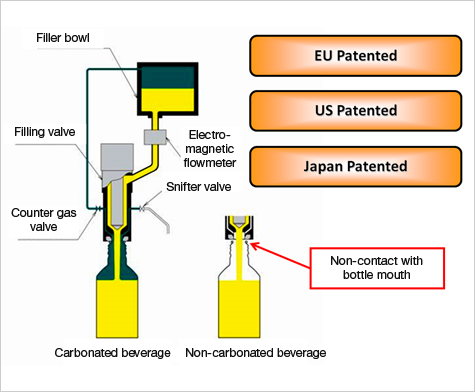

Flexible Filling System for Carbonated and Non-Carbonated Products

Shibuya provides unique technology to fill both carbonated and non-carbonated beverages using only one filler. There is non-contact fill for aseptic filling while there is contact fill for CSD filling. This system is also capable of filling CSD with high juice contents.

Shibuya Vent Tubeless Aseptic Filling Valve

- Decontamination Technology

- Decontamination level: Up to 6 log reduction value

- Double decontamination method with peracetic acid and hydrogen peroxide for the chamber cleaning and decontamination process

- Aseptic System Design

- Clean design for aseptic filler (No dead leg nor steam condensation pool)

- Aseptic chamber: Dynamic sealing of rotating and stationary parts (Filler and Capper)

- Filling & Capping Capability

- Fill all sensitive beverages, high and low-acid, with and without particles, and even with UHT milk.

- Aseptic Particle filling capability: up to 5mm (one stage filling), up to 10mm (two stage filling) with proven effective CIP/SIP method

- Multi-purpose filling valve (Still, CSD and CSD with high juice contents)

Vent Tubeless Filling Valve

- ・Mouth of bottle does not come into contact with liquid.

- ・Still product is filled by non-contact filling.

- ・Condensation of carbonated gas is not required to be controlled.

- System Output

- Output: 400bpm to 1200bpm(or 24000bph to 72000bph)

- Packaging Flexibility

- Allows greater freedom in bottle design (round, rectangular, square, or any shape or stand alone) / enables reduction of bottle weight

- Quick & Automatic Changeover

- Quick & Automatic packaging changeover without breaking sterility (between small PET and Large PET)

- Two neck profile handling (various closure size 28mm ~ 38mm) and quick changeover without breaking sterility

- Filling Capability

- Multi-purpose filling valve (Still, CSD and CSD with high juice contents)

- Same filling valve for dairy, juice and smoothie (up to 1000 cps)

- Product Safety

- Chemical residual: less than 0.5ppm

- Productivity

- High productivity and system efficiency (≥95%)

- The simplified liquid path with no irregular surface allows efficient washing and sanitation

- Maintain beverage safety in case of extended or emergency stop

- Reliability

- 100% filling & capping data collection and monitoring

- Programmable filling cycles to minimize foaming and splashing

- An electromagnetic flowmeter especially developed for filling applications and filling volume correction system ensure accurate filling