ESL Filling Systems

(H2O2/PAA Bottle Decontamination)

Extended Shelf Life Filling for Dairy Products

Numerous trends are driving the dairy and "on-the-go" beverage markets with the highest demand being longer shelf life. Shibuya's ESL systems are built to the same high quality standards as our proven aseptic systems. We have installed over 100 ESL Net Weight Filler systems worldwide and with our expert knowledge in dairy filling systems, we have created the most efficient and safest ESL system around.

Ultra-clean chamber environment

The container sanitation, filling and sealing operations are all carried out in an ultra-clean chamber environment with the chambers being equipped with automatic cleaning and sanitizing systems.

- Decontamination Technology

- Bottles are sanitized using H2O2 or peracetic acid (PAA) and foil/caps are sanitized using ultraviolet light (UV) or pulsed light

- ESL System Design

- Smaller footprint for ESL than an Aseptic Filler

- Positive air pressure control to maintain ultra clean environment

- Clean design for ESL filler (No dead leg nor steam condensation pool)

- Filling & Capping Capability

- Net weight filling is used allowing for precise accuracy and simplified, automatic CIP/SIP

- 100% individually controlled servo motors for reliable capping

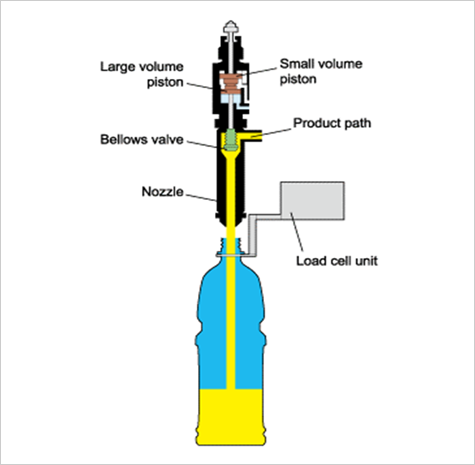

Net Weight Filler

This system fills containers to a preset fill weight using a loadcell mounted on neck gripper which directly controls the filling valve operation. The weight filler is able to accommodate a wide variety of bottle sizes.

Net weight filling accuracy is σ=0.3g based on 500g.

To ensure accuracy of weight measurements during filling, the system adjusts for the centrifugal force of the machine rotation.

- System Output

- Output: 400bpm to 1200bpm(or 24000bph to 72000bph)

- Packaging Flexibility

- PET and HDPE bottle (60ml~3800ml)

- Quick & Automatic Changeover

- Quick & automatic packaging changeover without breaking sterility (between small and large bottles)

- Two neck profile handling (within 10mm of on another) can be accommodated

- Filling Capability

- Same filling valve for dairy, juices and smoothies (up to 1000 cps)

- Product Safety

- No preservatives required

- Longer product shelf life - enabling extended "best-before" dates

- The container decontamination, filling and sealing operations are all carried out in an ultra-clean chamber environment

- Productivity

- High productivity and system efficiency (≥95%)

- Filling volume can be adjusted easily using the operation panel, reducing bottle changeover times

- The simplified liquid path with no irregular surfaces allows for efficient washing and sanitation

- Reliability

- The weight control algorithm automatically corrects for the effects of centrifugal forces due to the filler rotation

- Clean design for ESL filler (no dead leg nor steam condensation pool)

- Safety devices are included throughout system to prevent damage to equipment and protect operators