MACHINING SYSTEMS

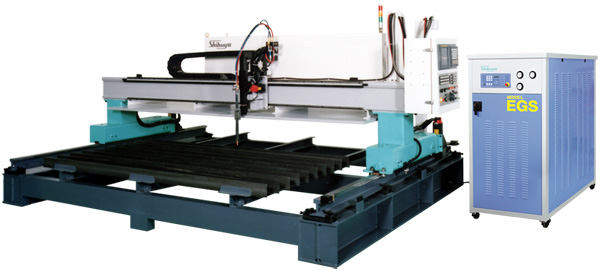

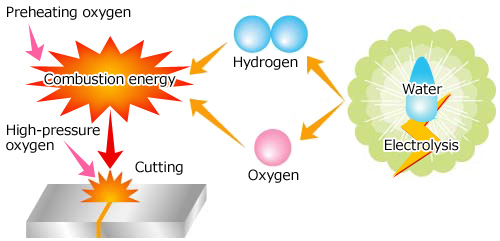

EPOCS Hydrogen Gas Cutting SystemsThis system is for cutting steel materials by creating hydrogen gas flames from hydrogen generated by electrolysis of water. Using water as fuel achieves a low-cost machine that is environmentally friendly.

EPOCS

Model HGC3500T+Model EGS12000

Principle

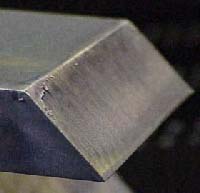

Improvement of cutting surface quality

Because the cutting surface is smooth with little slag and notches, secondary machining is either not required or simplified, thereby leading to smooth transfer to subsequent processes.

HGC Hydrogen Gas Cutting Systems

| Model | HGC3500T | HGC4000T | HGC4500T |

|---|---|---|---|

| Rail span | 3500 mm | 4000 mm | 4500 mm |

| Rail length | 3000 to 6000 to 9000 mm | ||

| Horizontal stroke | 2500 mm | 3000 mm | 3500 mm |

| Effective cutting length | 1250 to 7250 mm | ||

| Effective cutting width | 2500 mm | 3000 mm | 3500 mm |

| Machine height | 1320 mm | ||

| Machine weight | 400 kg | 450 kg | 500 kg |

| Power consumption | 3-phase, 200 V, 19.7 kW | 3-phase, 200 V, 20.7 kW | 3-phase, 200 V, 21.7 kW |

- Prepare either a 3-phase/3-wire, 200 Vac power source or a 3-phase/4-wire, 400 Vac power source.

- ■Specifications are subject to change due to constant improvements.

Hydrogen Gas Generator

| Model | EGS12000 |

|---|---|

| Hydrogen generation amount | Max. 8000 lit/h |

| Oxygen generation amount | Max. 4000 lit/h |

| Continuous supply pressure | Max. 0.35 MPa |

| Power consumption | 50 kWh |

| Water consumption | Max. 6.5 lit/h |

| Dimensions | 980 × 1530 × 1800 mm |

| Machine weight | 800 kg |

- ■Specifications are subject to change due to constant improvements.

- Inquiries

-

SHIBUYA CORPORATION

Mechatronics Div., SILAS Sales Dept.

2-232 Wakamiya, Kanazawa, Ishikawa 920-0054 JAPAN

TEL +81(76)263-8111 FAX +81(76)262-2210

E-mail sl-info@shibuya.co.jp