MACHINING SYSTEMS

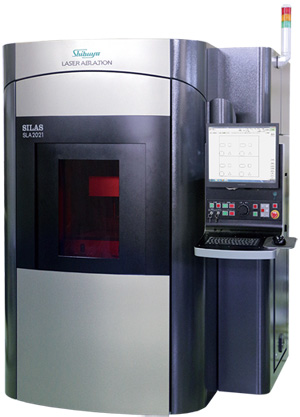

SLA Series Laser Ablation MachinesModel SLA Series

Model SLA2021

Features

- Laser ablation machine equipped with short pulse laser resonators can process a wide range of materials including glass, resin, composite materials such as CFRP, and metal foils such as aluminum, copper, and stainless steel by suppressing thermal effects.

- Laser ablation processing achieves higher quality processing than conventional laser processing (thin film removal,micro hole drilling, micro grooving and cutting).

- Laser ablation machine is suitable for contour cutting of FPC and cover lay film cutting such as PI,PTFE and LCP.

- Non-thermal cutting achieves high quality cutting with less carbonization, minimize HAZ, and less burrs compared to traditional laser cutting.

- Cutting with suppressed thermal effects can shorten your manufacturing.

- Laser ablation processing enables micro grooving even with hard materials.

- Laser ablation processing is excellent for thin film removal processing. such as ITO, Ag and Cu without damaging the substrate.

- The laser resonator is selectable from a pico-second type and nano-second type laser resonator according to application, and cutting in areas where the conventional pulse laser (micro-second pulse) could not achive.

- Specific heat treatment to minimal area is also possible.

- The irradiation optical system is selectable from the beam scanning method and fixed optical method.

- Ablation processing realizes high quality CFRP cutting so that the lamination state of CFRP can be confirmed.

| Ablation | Thermal cutting (conventional laser) |

|

| Cutting condition | Instantaneous evaporation | Melting |

| Laser type | Ultraviolet light through infrared light | Infrared light |

| Pulse width | Several nanoseconds or less (with nanosecond laser) 20 picoseconds or less (with picosecond laser) |

Several tens of microseconds or less |

Cutting examples

Glass 60 × 40 mm, t0.7 mm

Left: Soda-lime glass

Center: Reinforced glass

Right: Alkali-free glass

Resin 60 × 40 mm, t0.1 to t0.2 mm

Left: Polyimide

Center: PET

Right: PP

Polyimide 60 × 50 mm t0.05 mm

CFRP

40 × 25 mm, t0.6 mm

CFRTP

40 × 25 mm, t1.3 mm

Copper foil

40 × 25 mm, t0.2 mm

CFRP(Carbon Fiber Reinforced Plastics)

CFRTP(Carbon Fiber Reinforced Thermo Plastics)

- Inquiries

-

SHIBUYA CORPORATION

Mechatronics Div. Specialized Machine Div. Sales Dept.

2-232 Wakamiya, Kanazawa, Ishikawa 920-0054 JAPAN

TEL 076-262-2216 FAX 076-262-2210

E-mail sh-info@shibuya.co.jp