MACHINING SYSTEMS

LAMICS Laser / Water Jet Cutting SystemLaser and water jet cutting realizes high quality and fine cutting that could not be done with conventional laser. An innovated machine, free of thermal effects and free of spatter processing can be achieved thanks to the water jet that is emitted coaxially with the laser. This unique machine is suitable for film cutting, thin tubes micro cutting and silicon wafers cutting and so on.

Laser cutting with minimized thermal effects, dross and debris.

LAMICS combines laser and water jet cutting technologies, thereby gaining the features of both technologies to achieve laser cutting with minimized thermal effects, dross and debris.

| Cutting accuracy | Cutting speed | Thermal effects | Dross/debris | |

|---|---|---|---|---|

| Laser (dry) | ○ | ○ | × | × |

| Water jet | × | × | ○ | ○ |

| LAMICS | ○ | ○ | ○ | ○ |

Focus adjustment not required

LAMICS uses a laser beam sealed within a water jet having a length of several tens of mms while maintaining sufficient energy for machining. Focus adjustment is not required within the length that the laser beam is sealed in the water jet.

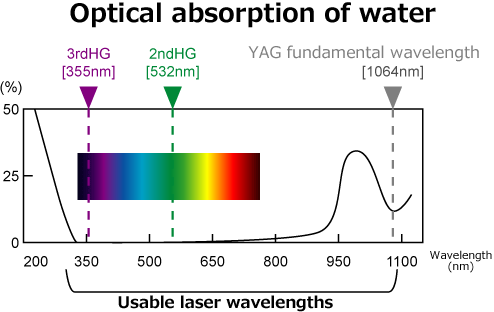

Laser beams of wavelengths with low water absorption can be sealed within a water jet. With YAG laser, the fundamental wave through to the third harmonic wave can be used.

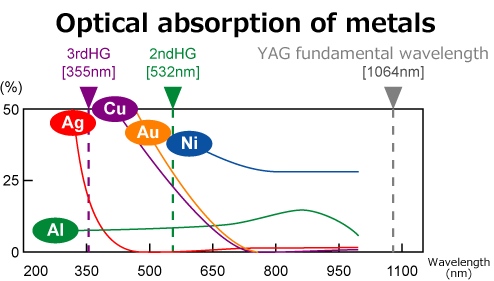

Optical absorption properties of metalsIn general, metals absorb laser beams with short wavelengths. Therefore, selecting a wavelength suited to the absorption properties of the material to cut makes actual cutting easier.

- Inquiries

-

SHIBUYA CORPORATION

Mechatronics Div. Specialized Machine Div. Sales Dept.

2-232 Wakamiya, Kanazawa, Ishikawa 920-0054 JAPAN

TEL 076-262-2216 FAX 076-262-2210

E-mail sh-info@shibuya.co.jp