PHARMACEUTICAL MANUFACTURING SYSTEMS

Ampoule Filling SystemThis system is for aseptically filling ampoules and comprises a washing machine, dry sterilization machine, and a filling / sealing machine. Because isolators for this system are also designed in-house by Shibuya, smooth operation together with an isolator is assured.

Based on extensive experience, we will propose the optimum filling and transfer system for your needs.

- We build and propose the best system for formulation based on various filling methods.

- Combination with Shibuya-designed isolators or RABS units can be achieved with optimum connections.

- Washing machines and dry sterilization machines as well as peripheral equipment can be designed and manufactured by Shibuya to establish optimum lines.

- A machine for inspecting the carbonized shape after sealing can also be incorporated.

Ultrasonic washing machine

Uniform irradiation time is ensured in ultrasonic washing and vials are inverted at the washing unit for efficient washing.

Dry sterilizing tunnel

Depyrogenation is performed by a hot circulation method which maintains a cleanroom class 100 status. Sterilization of the cooling unit is possible by either dry heat sterilization or gas decontamination.

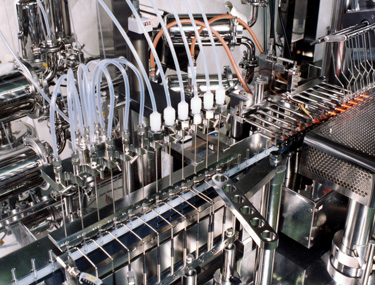

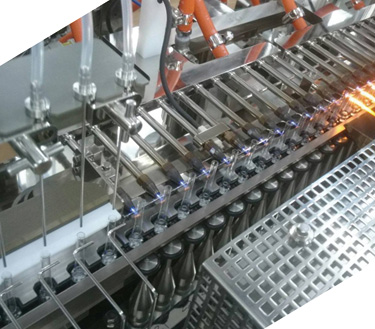

Ampoule filling / sealing machine

Transfer rakes allow fast but stable transfer. A filling method can be selected from various types and an IPC automatic sampling unit is provided.

- Inquiries

-

SHIBUYA CORPORATION

International Plant Sales Div.

Ko-58 Mameda-Honmachi, Kanazawa, Ishikawa 920-8681 JAPAN

Telephone : +81(76)262-1615 Fax : +81(76)223-1795

E-mail packaging@shibuya.co.jp