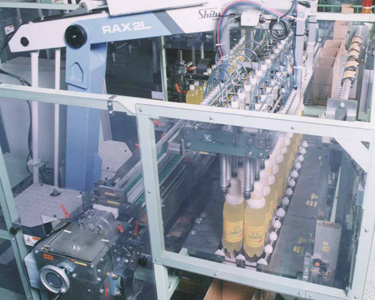

BOTTLING SYSTEMS

Beverage Bottling System

to accommodate your ever-changing beverage portfolio!

Beverage manufacturers are introducing new varieties of products and trying to provide more value -added products in order to meet the growing consumer demands.

Using energy saving processes, fewer resources, and complying with stringent quality standards allows us to meet the growing demands for food safety.

Shibuya understands the market's demands accurately and has risen to the challenge of meeting these diversified needs.

Shibuya has installed over 160 of our flexible aseptic filling systems at prominent brand owners with great success and have provided them with unparalleled options.

- US FDA compliance for low acid filling

- “All-in-One” system

- Low and high acid products

- PET & HDPE bottles

- Aseptic CSD and non-CSD filling

- 28mm and 38mm neck

- Bits filling – up to 5mm cube (1 filler) and up to 10mm cube (2 filler setup)

- Auto-changeover without breaking sterility

- Over 200 hours of continuous aseptic production

- High productivity and system efficiency (>95%)

- Zero spoilage in over 15 billion filled bottles to date

- Enables reduction of bottle weight

- Causes no thermal degradation of products

- Enables transport and storage at room temperature

- Enables extension of best-before dates

- Allows greater freedom in bottle designs

- Net weight filling method for high accuracy

- 100% filling & capping data collection and monitoring

- Programmable filling cycles to minimize foaming/splashing

- Individually controlled servo motors for reliable capping

Bottle Sterilization System

There are mainly two systems for sterilizing bottles: the EB bottle sterilizing system peroxide. which sterilizes PET bottles by utilizing the energy of electron beams and the H2O2 sterilizing system which uses hydrogen.

This aseptic filling system using the hydrogen peroxide sterilization method is approved by the FDA.

- Perfect sterilizing is assured by spraying hydrogen peroxide evenly both inside and outside the bottles.

- The sterile water rinser may be downsized or not required, allowing for a substantial reduction of water usage.

- Employing the Synchro System drastically reduces the footprint of the entire system.

Shibuya's EB sterilization is the first method in the world, which carries out the bottle sterilization by irradiating the Electron Beam to PET bottle. This method does not use the water or chemicals to sterilize the bottle so running cost is low and enviornmentally friendly.

In the EB sterilization system the entire bottle is irradiated, creating the most efficient sterilization possible.

- Reduction of total cost of ownership (TCO)

- Proven quick return on investment (ROI)

- One-man Operation

- No chemicals or water required for bottle sterilization

- No chemical residual risk

- Effective for all targeted microorganisms

- Quick validation, fewer CCP’s

- Smaller footprint

- Reduction of CO2 emissions

- Clean and safe operation

- Seven (7) E-Beam Aseptic Filling Systems running production world-wide

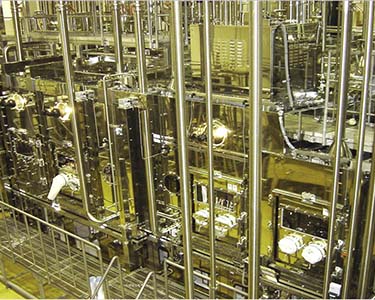

Filling technology

This filler fills containers to a preset fill weight using a loadcell mounted under the bottle rest to directly control the filling valve operation. The weight filler is able to accommodate a wide variety of bottle sizes.

- The simplified liquid path with no irregular surface allows efficient washing and sanitation.

- The weight control computer automatically corrects for the effects of the centrifugal forces of the filler rotation.

- Addition-ally the automatic zero and tare weighing functions combine for accurate fill weighing regardless of machine speed.

- Fill weight adjustment is accomplished quickly and precisely using a keyboard.

In this liquid filler flowmeters connected directly to the filling valves control filling to a constant volume. Model VFF can handle various sized bottles.

- The simplified liquid path with no irregular surface allows efficient washing and sanitation.

- An electromagnetic flowmeter especially developed for filling applications and filling volume correction system ensure accurate filling.

- Filling volume can be adjusted easily using switches on the operation panel, reducing size-change time.

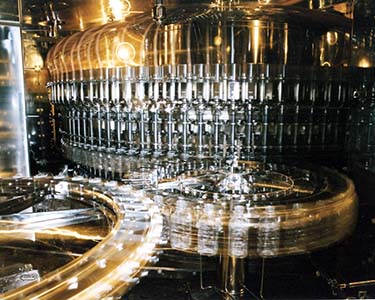

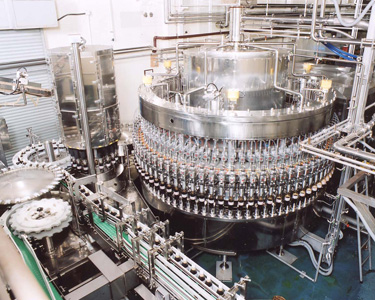

Beverage Filling System for Carbonated and Non-carbonated Product

This carbonated beverage filling system combines high reliability with high speed, accurately filling bottles at speeds up to 1000 bottles per minute. We manufacture systems which can be used to produce both carbonated and non-carbonated products as well as systems for filling cans.

Carbonated Beverage Filler / Capper

Caser

Total Customer Support

Shibuya goal is for long-term customer satisfaction. We support total cost reduction.

- Attentive customer support

- Shorter equipment installation period

- Reduce aseptic validation lead times

- Fewer changeover times

- Increase line efficiency

- Tech support & microbiology expertise

- INQUIRES

-

SHIBUYA CORPORATION

International Plant Sales Div.

Ko-58 Mameda-Honmachi, Kanazawa, Ishikawa 920-8681 JAPAN

Telephone : +81(76)262-1615 Fax : +81(76)223-1795

E-mail packaging@shibuya.co.jp